Industrial Machines: Backbone of Modern Manufacturing

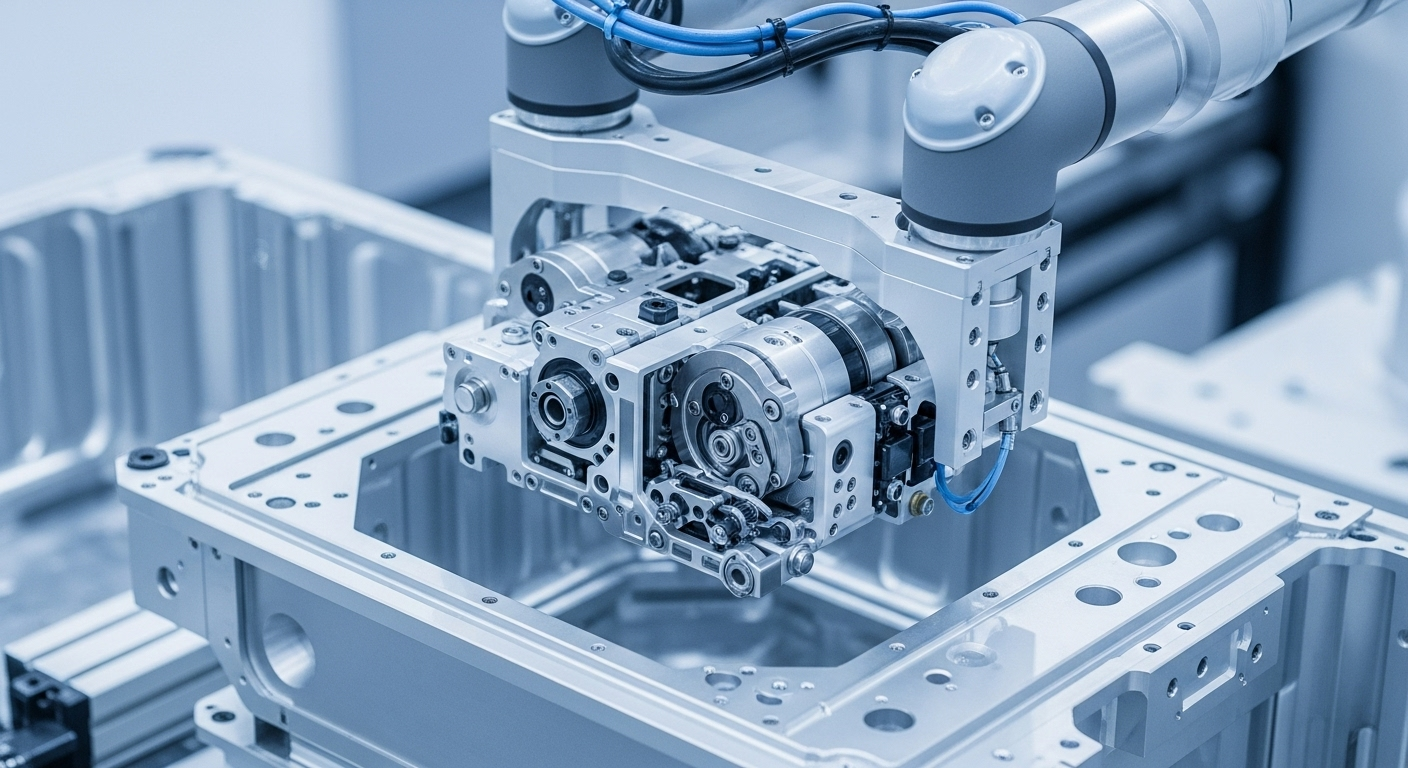

Manufacturing has evolved dramatically over the past century, transforming from labor-intensive processes to sophisticated automated systems. At the heart of this transformation lie industrial machines - complex mechanical systems that have revolutionized how products are designed, produced, and delivered to consumers worldwide.

Manufacturing industries worldwide depend on sophisticated machinery to transform concepts into tangible products. These complex systems represent decades of engineering innovation, combining mechanical precision with digital intelligence to create the products that define modern life.

How Advanced Equipment Drives Efficiency in Modern Manufacturing

Efficiency in manufacturing stems from the seamless integration of automated systems that minimize human error while maximizing output. Computer Numerical Control (CNC) machines exemplify this principle, executing programmed instructions with microscopic precision. These systems reduce material waste by up to 30% compared to manual operations while maintaining consistent quality across thousands of production cycles. Advanced sensors monitor performance in real-time, automatically adjusting parameters to optimize throughput and prevent defects.

The Role of Manufacturing Equipment in Shaping the Future of Production

Emerging technologies are reshaping manufacturing landscapes through intelligent automation and predictive maintenance capabilities. Machine learning algorithms now analyze production data to identify patterns and optimize workflows autonomously. Internet of Things (IoT) connectivity enables remote monitoring and control, allowing operators to manage multiple facilities from centralized locations. Additive manufacturing technologies, including 3D printing systems, are revolutionizing prototyping and small-batch production by eliminating traditional tooling requirements.

How Advanced Manufacturing Systems Improve Production Processes

Modern manufacturing benefits from equipment that integrates multiple functions within single platforms. Multi-axis machining centers combine milling, turning, and drilling operations, reducing setup times and improving dimensional accuracy. Collaborative robots work alongside human operators, handling repetitive tasks while workers focus on complex problem-solving activities. Vision systems inspect products at production speeds, identifying defects that would be impossible to detect manually.

Why Manufacturing Equipment Is Essential for Today’s Production Success

Competitive manufacturing requires consistent quality, reliable delivery schedules, and cost-effective production methods. Automated systems operate continuously with minimal supervision, maintaining production schedules that would be impossible with manual labor alone. Quality control systems ensure products meet specifications before leaving the factory floor, reducing warranty claims and customer complaints. Flexibility in modern machinery allows manufacturers to adapt quickly to changing market demands without significant retooling investments.

How Manufacturing Systems Enhance Productivity and Reduce Costs

Productivity improvements from automation translate directly into cost reductions across multiple operational areas. Energy-efficient motors and optimized cutting parameters reduce utility expenses while extending tool life. Predictive maintenance systems prevent unexpected breakdowns, eliminating costly production interruptions and emergency repairs. Labor costs decrease as machines handle tasks previously requiring multiple workers, allowing companies to redirect human resources toward higher-value activities.

| Machine Type | Typical Cost Range | Key Benefits |

|---|---|---|

| CNC Machining Center | $150,000 - $800,000 | High precision, automated operation |

| Robotic System | $50,000 - $300,000 | Consistent quality, 24/7 operation |

| Injection Molding Machine | $80,000 - $500,000 | High volume production, minimal waste |

| Laser Cutting System | $100,000 - $1,200,000 | Precise cuts, minimal material waste |

| Automated Assembly Line | $200,000 - $2,000,000 | Increased throughput, reduced labor costs |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Investment in advanced manufacturing equipment requires careful consideration of production requirements, available space, and long-term business objectives. Companies must evaluate total cost of ownership, including maintenance, training, and potential upgrades when selecting machinery. The rapid pace of technological advancement means that equipment purchased today may require updates or replacements within five to ten years to maintain competitive advantages. However, the productivity gains and quality improvements achieved through modern manufacturing systems typically justify these investments through increased profitability and market position.